The Art and Science Behind Cognac Distillation

The grape, specifically the Ugni Blanc grape, lies at the foundation of every cognac. Cognac, the luxurious spirit revered by many, is steeped in tradition and meticulous craftsmanship. At its core, cognac is made from an intricate distillation process that begins with a wine produced from these grapes, transforming it into a concentrated eau-de-vie.

But what really happens behind the cellar doors? Let’s delve into the world of cognac distillation.

Why Not-So-Great Wine Makes Great Cognac

Before diving into the heart of the distillation intricacies, it’s essential to address a commonly held belief: the wine used, known as Vin de Chaudière, isn’t necessarily top-shelf. Originating from the Ugni Blanc grape this wine boasts a high acidity, making it uniquely suitable for distillation. It’s relatively low in alcohol, averaging around 9%. Furthermore, the flavor profile isn’t particularly intense. Yet, this is by design. For the eaux-de-vie to truly shine, it needs a base that is low in alcohol and has a neutral aroma. Moreover, the acidity in this wine ensures better chemical reactions during the distillation process. Thanks to cognac production laws, these wines remain pure, free from additives or superficial enhancements, guaranteeing the authenticity of the liquid produced.

Cognac Distillation Process Demystified

So, how is cognac, our well-known French brandy, made from this ordinary wine?

To begin, the harvested grapes which cognac is eventually the result, have to undergo the fermentation process. It might seem odd but you need bad wines to produce good cognac. The juice made from grapes like this is very acidic and therefore not as enjoyable as a typical table wine. This wine made from Ugni Blanc grapes, undergoes no simple process. Its primarily made process lasts for several weeks, resulting in an alcohol content between 8-10%.

Distillation always takes place straight after the fermentation and can only last until the last day of March according to the Bureau National Interprofessionnel du Cognac (BNIC). The entire cognac production process is closely watched by the coordination and decision-making body for the Cognac industry. They do not only protect the cognac appellation and quality of cognac but also the cognac houses. One example being that the cognac ages for vintage cognacs are certified and checked.

Once the liquid from the grapes is done, distillation takes place. Distilling cognac happens continuously, day and night, within the copper pot still used in the cognac region.

Turning wine into Cognac

Craftsmen fill, monitor, and choke the traditional Charentais copper stills. This process, designed to transform wine into cognac wine, relies on the volatile components of the liquid. Long, delicate distillation preserves the wine’s aromas.

Not once but twice

To make cognac, not one, but two distillation stages are required. In the first stage, a raw spirit called “brouillis” is extracted. The second distillation stage produces a much higher alcohol content. Only the middle part, the “heart”, is preserved. This clear, colorless liquid is called eau-de-vie.

12 KG – 9 LITERS – 1 LITER

It takes around 12 kg of grapes to produce 1 liter of eau-de-vie. Pressing the grapes produces 9 liters of wine. A first distillation yields 3 liters of brouillis. A second distillation yields 1 liter of pure eau-de-vie and marks the end of the distillation.

Visit a distillery during this time, and it’ll resemble a cozy abode, equipped with beds and TVs, as the cognac producer often stays onsite throughout.

La Bonne Chauffe

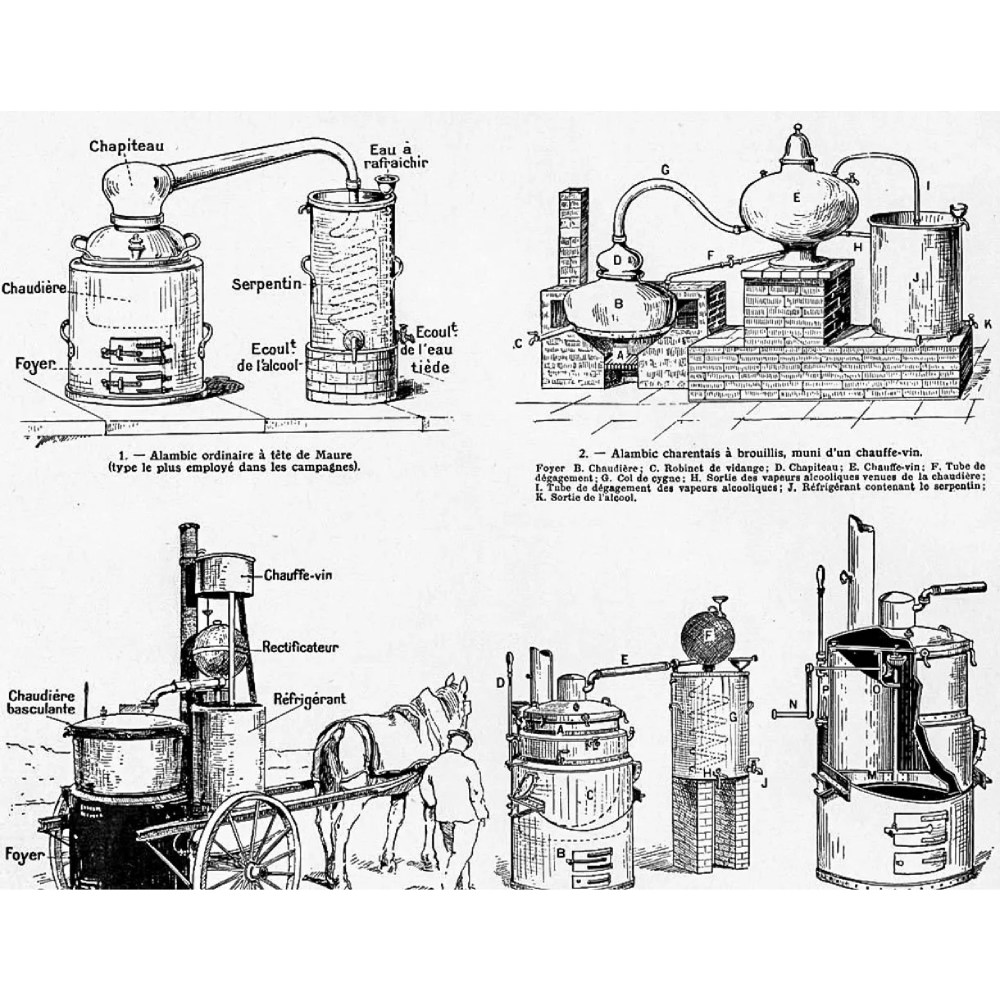

The real magic occurs within the confines of the traditional copper pot stills, known as “Alambic Charentais” or simply “alembic.” These stills comprise three main components: the chaudiere (boiler), chapiteau (condenser), and chauffe-vin (wine-warmer). These stills’ design is so crucial that their dimensions are regulated by law.

The wine-warmer preps the wine before it moves to the boiler. Here, the process involves two crucial stages, aptly termed “double distillation.” The first distillation produces a raw eau-de-vie known as brouillis, which is then distilled a second time, refining it further, capturing only the essence, or the “Coeur” (heart), discarding the tete (head) and queue (tail). This method is not merely a tradition but a legal requirement.

Now, if you’re imagining distillation as simply boiling a liquid and capturing its vapors, you’re on the right track. The vapor, when cooled with distilled water, condenses back to a liquid. The artistry and science of the distiller, or the cellar master, determine the uniqueness of each eau-de-vie.

Here comes a great video about Cognac distilling, the distillation process. The birth of Cognac is a great video about the process of double distilling, creating the world-famous eaux-de-vie.

If you are interested in the process, and the details, take a look at our informative article about distilling Cognac.

Eau-de-Vie: The Soul of Cognac

Translating to ‘brandy’ from French, eau-de-vie is the heart and soul of cognac. This type of brandy, the product of the aging process, undergoes maturation in oak barrels which requires a minimum of two years, undergoing further transformations over time, leading to the creation of the blend.

Big and major cognac houses such as Hennessy cognac but also smaller producers such as our beloved neighbor and friends from André Petit passed on for generations after generations what making cognac involves. Once the end of distillation is done and the process is complete the brandy that comes out in a superior old pale color is set to rest in French oak barrels. Cognac is the result, not only of the grapes grown in the region but also portraits the people dedicated to cognac.

Cognac production process – summary

In essence, while the fundamental process may sound straightforward, creating cognac involves nuances and expertise. Different crus, or vineyard regions, produce varying qualities of grapes, impacting the final product. Every decision, from discarding the heads to identifying the heart, relies heavily on the experience of the cellar master. At the very end, it’s up to the cellar master to do the process known as cognac blending. This often occurs for the standard range of a cognac brand.

So, the next time you sip on that elegant glass of cognac, remember the journey it took from vine to barrel to bottle, a journey of art, science, and passion.

![Cognac Distillation: Birth of the Spirit [Video] Cognac Distillation: Birth of the Spirit [Video]](https://blog.cognac-expert.com/wp-content/uploads/2011/01/Cognac-Distillation-Process-1170x508.jpg)

![Cognac Distillation: Birth of the Spirit [Video]](https://www.cognac-expert.com/img/p/1/0/5/5/7/10557-home_default.jpg)

![Cognac Distillation: Birth of the Spirit [Video]](https://www.cognac-expert.com/img/p/1/0/5/5/6/10556-home_default.jpg)

![Cognac Distillation: Birth of the Spirit [Video]](https://www.cognac-expert.com/img/p/1/1/2/1/9/11219-home_default.jpg)

![Cognac Distillation: Birth of the Spirit [Video]](/wp-content/themes/cheerup-child/img/newsletter.png)

1 Comment

This is great to know about distillation process Cognac liquor.